Grinding with Sustainable Steel Expertise.

ABS Sfere is a European pioneer in sustainably sourced grinding media.

It is the ABS brand dedicated to grinding media, bringing all the knowledge and experience of a steel producer to serve the mining industry.

Why ABS Sfere

A premier European manufacturer of high-quality and sustainable grinding media.

Eco-sustainable quality that lasts over time:

- 94% of our raw material is recycled scrap steel, and our grinding balls are produced only using an EAF furnace.

- 100% made in Italy with high-quality steel from European scrap.

- -65% CO2 emissions compared to blast furnace steel production methods.

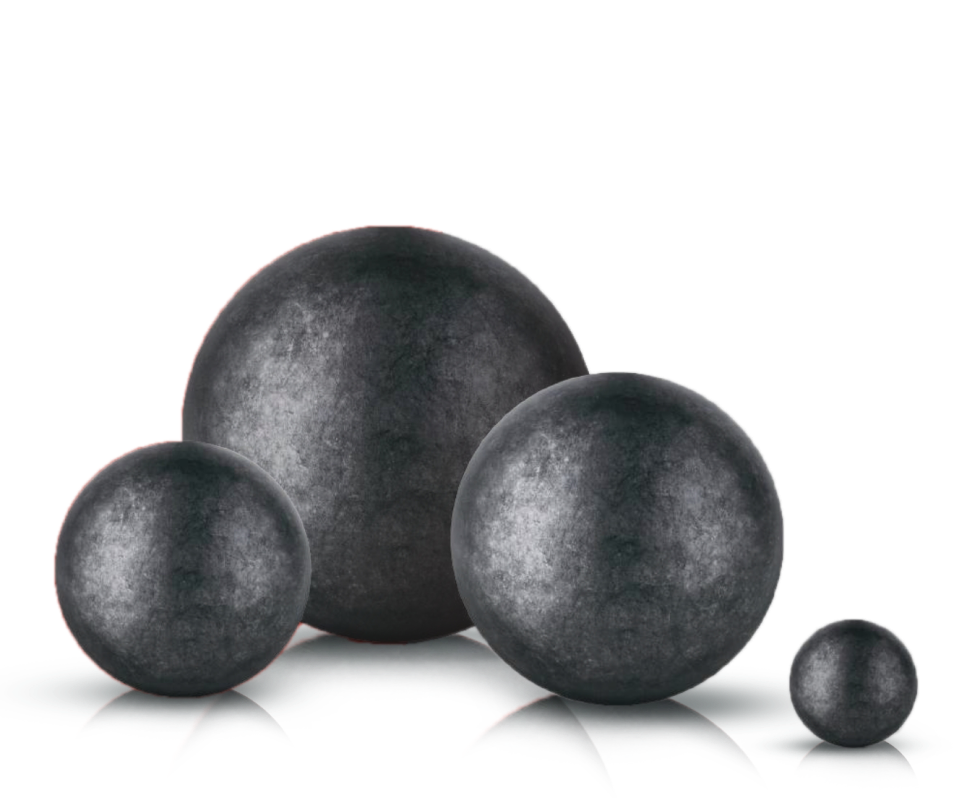

A European high-quality grinding balls manufacturer by capacity and range:

- Guaranteed raw material supply thanks to ABS scrap management

- 150,000 tons of forged grinding balls for the mining industry

- A wide product range. Two production lines provide a complete range of grinding balls from 30mm up to 150mm

Quality control tests:

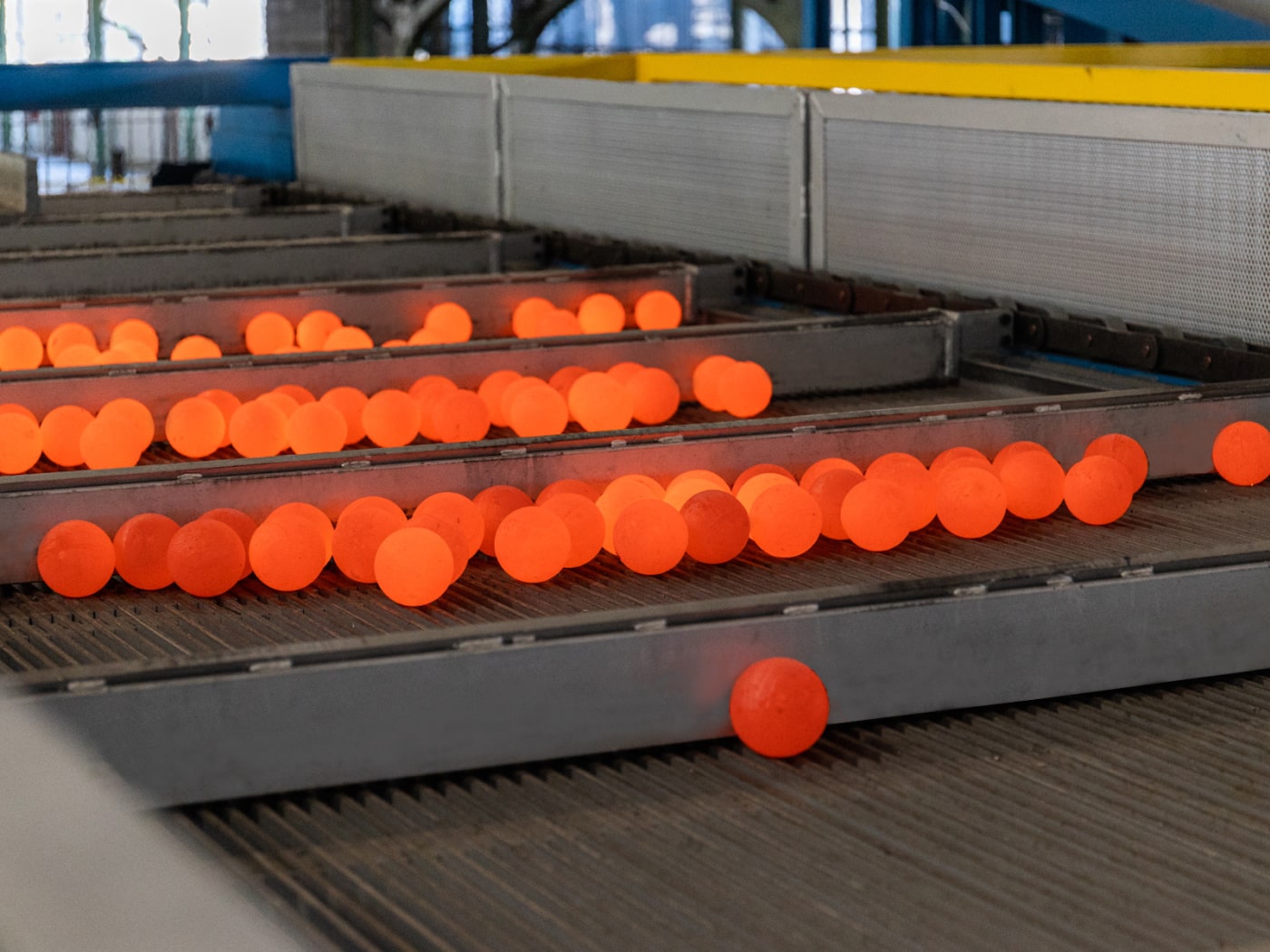

- Quality control throughout the entire production cycle

- Tailored heat treatment across the entire range: the martensitic structure obtained during the manufacturing of the grinding balls guarantees excellent hardness.

- SAG spheres undergo mechanical resistance testing to meet the specifications required by our clients.

ABS certifications:

– ISO 14001

– ISO 9001

– ISO 45001

Technical Support

-

- Support during both application and use of our grinding balls

- Processing plant personnel training courses

Logistics Support

-

- In-house logistics service: ABS Sfere guarantees carriage to the final destination of our products, if requested

- Delocalized warehouses in the different mining areas where grinding balls are used the most

- Customization of shipping packaging.

A product driven by research and development activities at the ACM Research and Development Centre.

- Tailored solutions: ABS Sfere meets every customer’s needs with custom alloys.

- Custom chemistry: grinding media’s chemical composition can be optimized to fit exact specifications.

- Specific heat treatments applied to obtain the best performance

- Exclusive SAG balls from Rotoforgia machine: additional heat treatments are currently being studied to further improve the metallurgical characteristics of our SAG balls range

Product

Technical specifications and quality range

ABS Sfere creates custom and sustainable grinding media based on the customer’s needs.

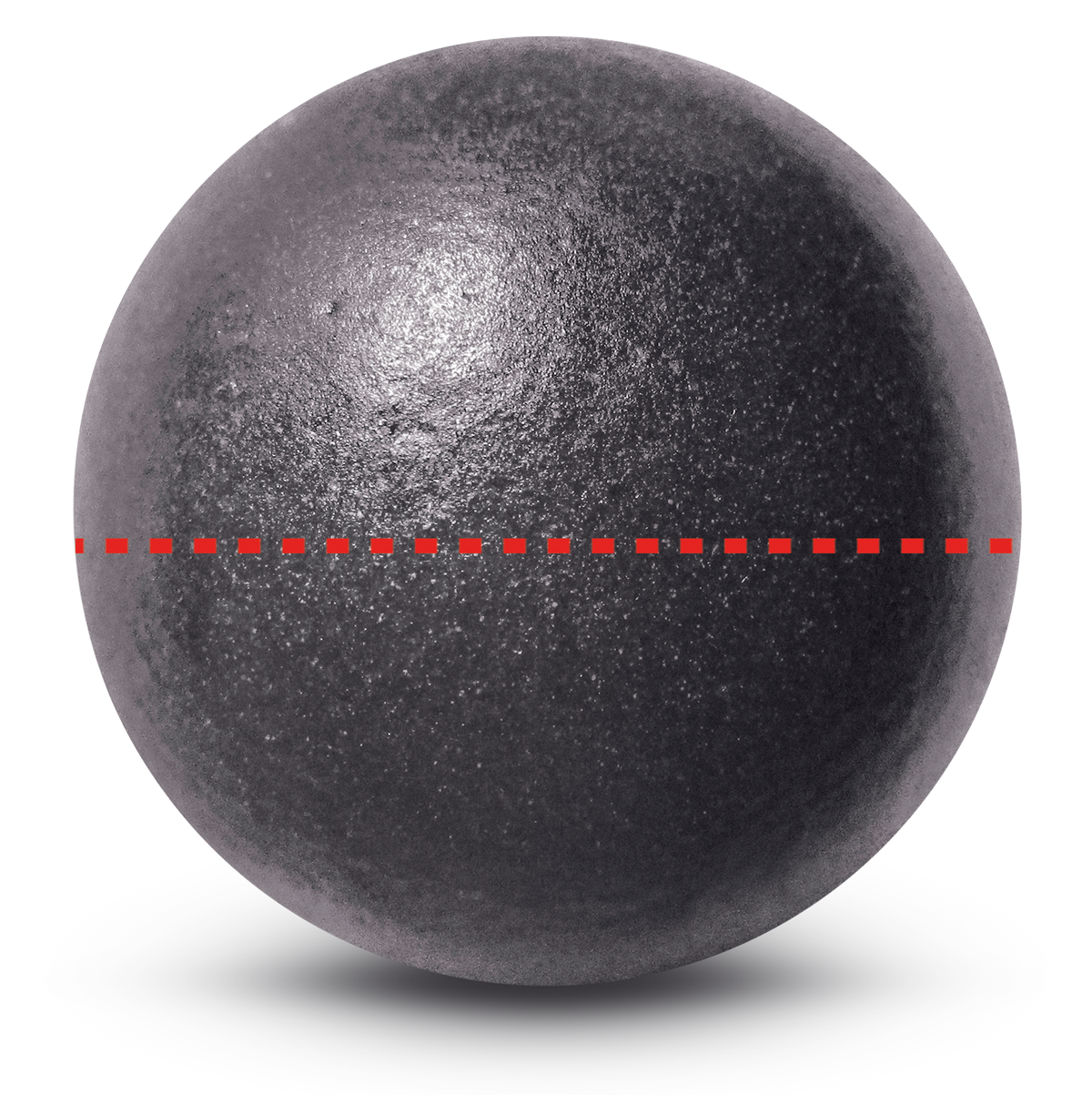

Quality, hardness and features signed ABS Sfere

A product tailored to each use case.

FULL HARDNESS

Hardness rockwell (hrc): 60 – 65

Main feature: High abrasion resistence

INTERMEDIATE HARDNESS

Hardness rockwell (hrc): 55-60

Main feature: Combining impact and abrasion resistance

REDUCED HARDNESS

Hardness rockwell (hrc): 48-55

Main feature: High impact resistance

about us

ABS Sfere: research and innovation by Acciaierie Bertoli Safau

ABS was created in 1988, by joining together hundreds of years of experience from two historical Italian companies: Acciaierie Bertoli and SAFAU . The union of these two companies under the Danieli Group, becoming its steel-making division, offers both specialization in steel transformation processes and technological innovation, which guarantee the best performance of grinding balls in all our customers’ applications.

Why ABS?

- We boast a unique range at a single site.

- We make more than 1,000 types fo steel grades, a variety that makes us unique in the international arena.

- In ABS we are constantly committed to improving the energy efficiency of our production processes to reduce CO2 emissions.

Because experience strengthens know-how.

ABS is the steel-making division of the Danieli Group

Danieli Group is the full cycle provider company from raw materials to finished products in the metals industry.

9,000+

Employees

4,349M€

Revenue

Want to learn more?

Fill out the form to be contacted.

Contatti